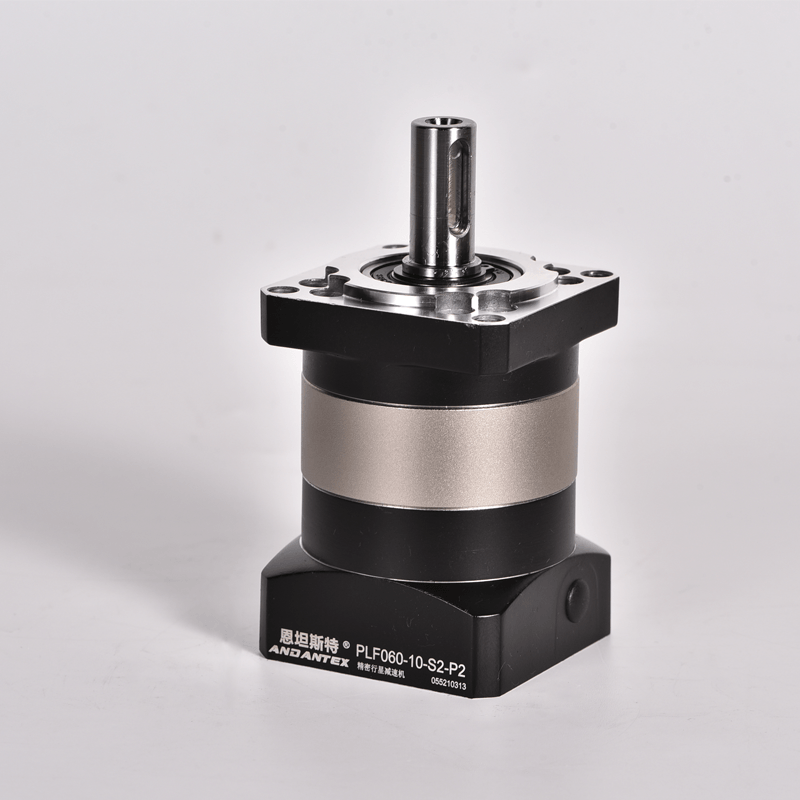

Features

The application of PLF planetary gearboxes in food machinery and equipment is mainly reflected in the following aspects:

High-precision control: PLF planetary gearboxes can provide high-precision motion control, which is suitable for food processing equipment that requires precise positioning, such as automated packaging and filling machines.

High Torque Output: The design of planetary gearboxes allows them to provide high torque output in a small footprint, which is important for food machinery when handling heavy or high loads.

Durability and low maintenance: PLF planetary gearboxes typically have a long service life and low maintenance requirements, which suits the continuous operation requirements of the food industry and reduces downtime.

Low noise: Noise control is an important factor in food processing, and the low noise characteristics of PLF planetary gearboxes help to improve the working environment.

Wide range of applications: In addition to packaging and filling equipment, PLF planetary gearboxes can be used in conveyor systems, cutting equipment and other automation equipment to improve overall productivity.

Applications

In automated food packaging equipment, accurate packaging speed and stable torque output are often required, and the high-precision design of PLF planetary gearboxes can adjust the output speed according to different packaging needs to ensure that the packaging effect of the product will not be affected under strenuous operation. At the same time, when the equipment is under full load, PLF planetary gearboxes can still ensure stable output torque, thus ensuring the continuity and stability of the packaging process.

Precise control: Hybrid stepper motors offer good positioning accuracy and repeatability, making them suitable for use in food processing equipment that requires precise control, such as packaging machines, filling machines and cutting machines.

High torque output: By adding a gearbox, the stepper motor is able to output higher torque at lower speeds, which is especially important for food machinery when handling heavy or high loads.

Smooth operation: Hybrid stepping motors run smoothly, and together with gearboxes, they can reduce mechanical vibration and noise, improving the working environment of food machinery and product quality.

Automation and Intelligence: In modern food production, the degree of automation is getting higher and higher, and the combination of hybrid stepper motors and gearboxes can realize more complex automation control, such as real-time monitoring and feedback systems, to ensure the stability and efficiency of the production process.

Corrosion resistance: Many food machines need to work in humid or corrosive environments, and choosing the right hybrid stepper motor and gearhead can improve the durability and extend the service life of the equipment.

Package content

1 x pearl cotton protection

1 x special foam for shockproof

1 x Special carton or wooden box